Furnace temperature curve

Solder curve

Welding and cleaning

Most production and field problems faced by users of unsealed switches are caused by internal switch contact contamination during welding and cleaning. The switch may operate intermittently (especially in low-power applications) and may be disconnected during factory test or subsequent field application. Careful handling during welding and cleaning can avoid most of the process pollution problems that may be encountered.

Both manual welding and equipment welding may cause pollution. Manual welding and cleaning must be performed by properly trained personnel using small diameter solder (0.030-0.040 inch) and low-power soldering iron (no more than 25-40 watts). The welding time shall not exceed about 3 seconds. Do not soak or spray the unsealed part of the switch with detergent during flux cleaning.

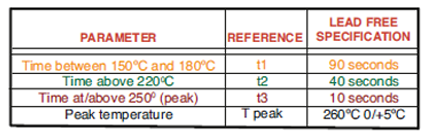

| Surface mount technology (SMT) reflow soldering curve reference | Reflow soldering curve of typical surface mount technology |

|  |

|

|

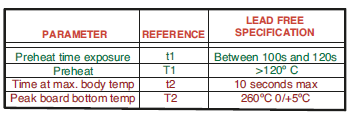

Wave soldering curve reference

Thermal shock resistance

Execute the temperature curve twice:

| |

Note: not all Cha products are tested according to this scheme. Please refer to the product information for details.